| +44 7833 797489 | info@spectrumservice.co.uk |

| +44 7833 797489 | info@spectrumservice.co.uk |

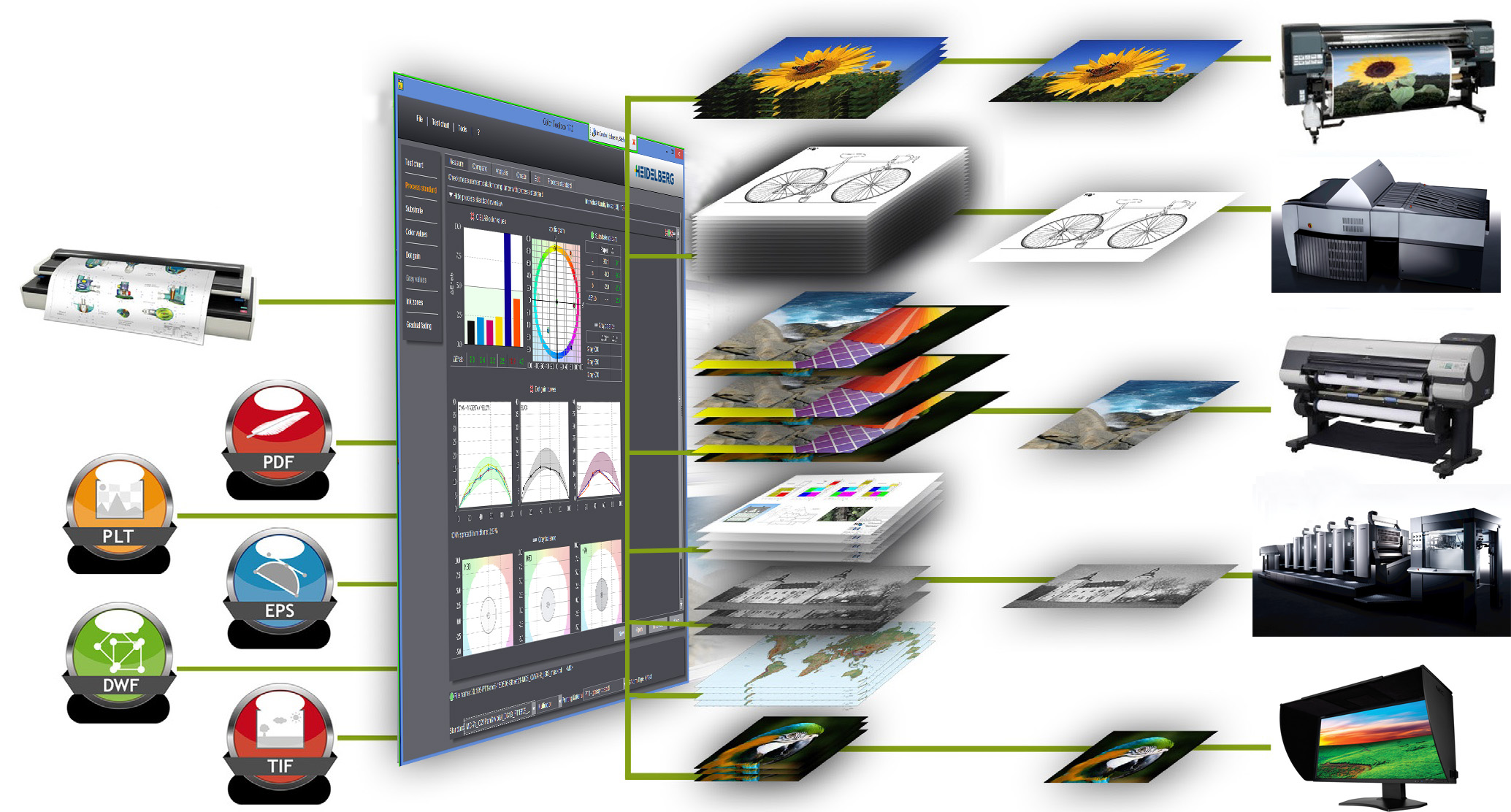

Print Color Management

Our in-depth knowledge and expertise in press fingerprinting and characterization are |

|

|

We provide training for color management, PDF creation, monitor and inkjet proof calibration, CtP & RIP settings. Our long-term experience also helps customers to achieve precise color values with multi color printing applications such as Hexachrome and Opaltone. |

We providing complete service with our leading hardware and software products in the field |

|

Measurement DevicesWe provide theoretical and practical trainings to the operators for densitometer, plate reader, spectrophotometer, automatic color measurement system devices and all the relevant standards to ensure maximum efficiency. |

MonitorsCustomer expectations for print quality are increasing day by day. Printing houses are aiming at investments that increase their efficiency and reduce the amount of waste to meet customer demands. One of the most important investment is "soft proofing". Thanks to soft proofing, problems can be noticed and thus material and time loss can be prevented in the first stage of the production. We provide color critical monitors from the NEC, one of the world's giant brands and Just-Normlicht products as standard daylight sources to set up reliable soft proof stations. |

PrintersIt is a vital necessity for the printing presses to be able to see how the colors will look on the paper before they start the printing. With the industry's most preferred printers and software, you can set up a proof station to ensure that your print results appear on the proof sheet at full accuracy. We provide all training to operators about the standards and calibrations. |

CTP(Computer to Plate)CtP (Computer to Plate) and the setting of the plate processor machines, greatly influence the print quality. What you need to do is to set the focus, exposure, and balance of the laser systems perfectly and set the processor machine parameters to keep the print quality and circulation at the highest level. With our deep knowledge and expertise provides all these settings for you on Heidelberg CTP machines especially. |

Printing PressesEfficient and standardized print production is possible with the optimization of printing machines. For increasing efficiency, we offers to optimizing the CIP4 information to the current plate, ink, ambient temperature, and machine condition. This optimization ensures that you reach on the first sheet the target color values and also the right ink density selection and dot gain adjustment. We aim to provide standard printing conditions in the printing press by giving necessary trainings to the operators. |